Solid State Technology

Semi-solid-state battery cells replace much of the flammable liquid electrolytes with highly stable solid state electrolytes

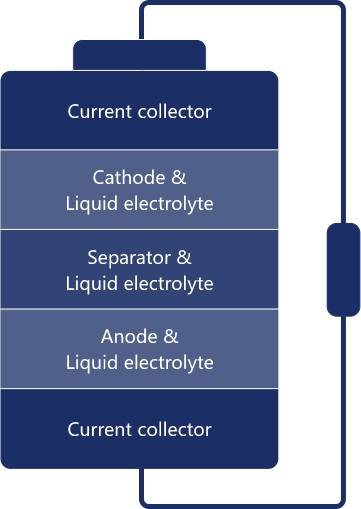

Conventional Li-Ion battery

WELION

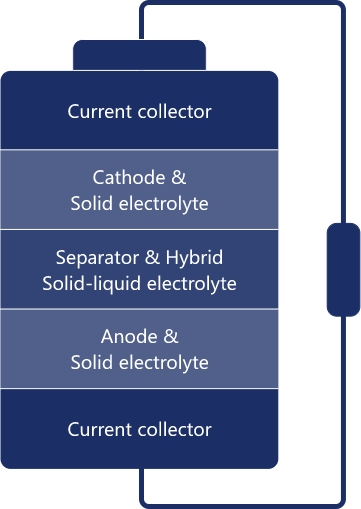

Semi solid state battery

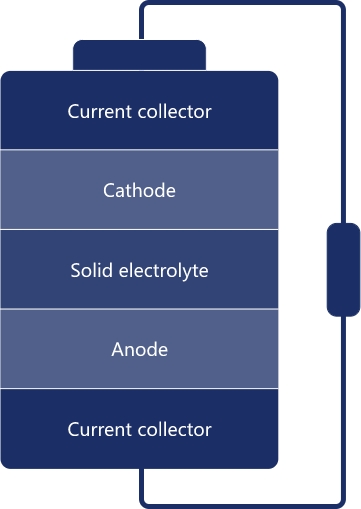

All solid state battery (ASSB)

The Semi-Solid State

Bridging the gap between

conventional liquid electrolyte cells and fully solid-state cells

WELION semi-solid-state battery

cells represent an intermediate state between conventional lithium-ion batteries with liquid electrolytes and

fully solid-state batteries. They take advantage of the properties of both technologies to increase safety and

energy density while controlling costs.

A safer hybrid electrolyte

A hybrid mixture of solids

and

liquid electrolyte is simply a safer chemistry

WELION semi-solid-state battery cells use a hybrid

electrolyte

which is comprised of solid matter surrounded by a liquid electrolyte. The resulting hybrid electrolyte results in

cells with a much lower risk of leakage, fire, and explosions that can occur in conventional lithium-ion batteries

with a fully liquid electrolyte as there is less flammable liquid in the cell. The unique chemistry also minimizes

the risk of „thermal runaway“, a problem that can occur with liquid lithium-ion batteries on the market today.

Energy density

Increasing energy density through innovative processes and materials

Batteries featuring WELION

semi-solid-state cells

offer higher energy density than conventional lithium-ion cells, thanks to our hybrid electrolyte chemistry,

innovative

cell structure, advanced materials, and cutting-edge manufacturing processes.

Processes:

- In-situ Solidified Electrolyte: Creates a stable and uniform electrolyte structure, improving battery safety

and longevity.

- Pre-lithiation of the Anode: Boosts the initial capacity and efficiency of the cells, ensuring superior

performance from the start.

- Special Mixing of the Solid Electrolyte: Optimizes ionic conductivity and mechanical strength, resulting in

higher energy density and better durability.

- Solid Electrolyte Coating of the Cathode: Protects the cathode material,

reducing degradation and extending the overall lifespan of the battery.

Materials:

- Ultra-thin Metallic Lithium Foil: Increases energy density, allowing for longer-lasting power in a compact

form.

- Ionic Conductive Separator: Improves ionic conductivity, enhancing the overall efficiency and safety of the

cell.

Despite these innovations, semi-solid-state cells have not yet matched the electrochemical properties of full solid-state cells, which will undoubtedly achieve even higher energy densities in the near future.

Controlling costs

Cost-efficient, scalable bridge technology between liquid and solid-state cells

Batteries

constructed with WELION

semi-solid-state cells are more cost-efficient and easier to produce at scale than fully solid-state

batteries.

Manufacturers can utilize existing lithium-ion battery processing equipment and methods in their production.

In

contrast, solid-state batteries require new and novel production methods. In this way, semi-solid-state

batteries

serve as a bridging technology.

Areas of application

Flexible technology for a multitude of applications

WELION semi-solid-state technology will play a particularly

important role in lightweight and high-performance electric vehicles (EVs) and energy storage systems, as it can

significantly increase range and capacity while decreasing charging times - key factors in driving the change

towards e-mobility. Due to the flexibility of WELION technology, our semi-solid-state cells also offers benefits

in applications such as portable electronic devices.

The historical development of battery cells can be divided into four important stages

1.

Lead-acid cell Invented in 1859, this was the first rechargeable battery. It uses lead plates and sulfuric acid, is heavy, and has a low energy density, but is still used today in cars and as a backup power source.

2.

Nickel-Metal Hydride (NiMH) This technology emerged in the 1980s and offered a higher energy density than lead-acid batteries. It is lighter, rechargeable, and was widely used in hybrid cars and portable devices.

3.

Lithium-ion

battery

Since the

1990s, lithium- ion batteries have dominated the market because they offer much higher energy density, lower

weight, and longer lifespan. They are used in smartphones, laptops, and electric vehicles, but have safety

issues (risk of ignition).

4.

Semi-solid-state battery This newer technology uses a hybrid solid/liquid electrolyte, which is safer and achieves higher energy densities without the high production costs of full solid-state batteries. It is considered a bridging technology towards solid- state batteries.

Each generation improved efficiency, energy density, and safety. The currently available WELION semi- solid-state battery cells have an energy density of up to 350 Wh/kg, making them among the most powerful battery cells on the planet.

Semi-solid-state battery This newer technology uses a hybrid solid/liquid electrolyte, which is safer and achieves higher energy densities without the high production costs of full solid-state batteries. It is considered a bridging technology towards solid- state batteries. Each generation improved efficiency, energy density, and safety. The currently available WELION semi- solid-state battery cells have an energy density of up to 350 Wh/kg, making them among the most powerful battery cells on the planet.

Battery Roadmap

2023

First WELION series semi-solid state production vehicle with 360 Wh/kg 111 Ah cells in NIO car. Range >1000 km on a single charge

2024

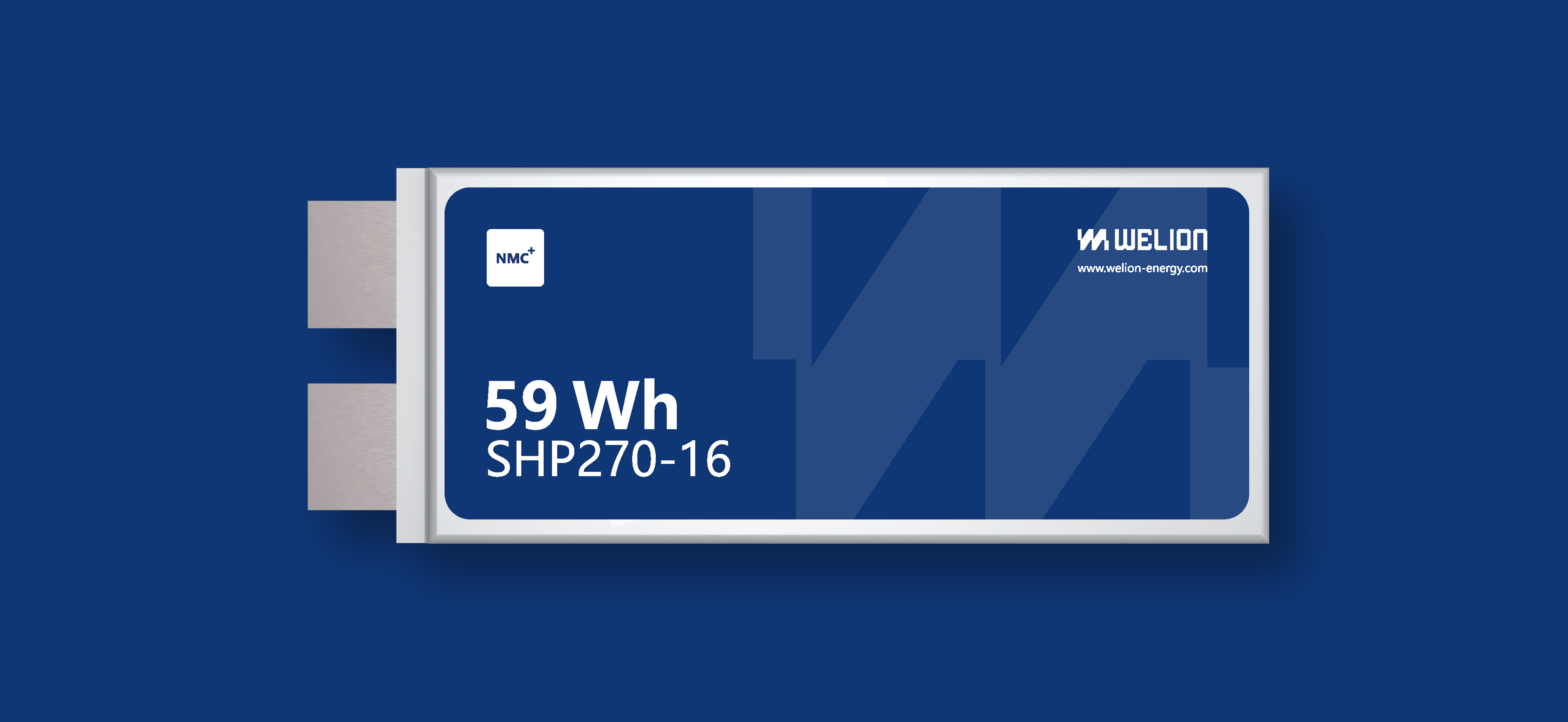

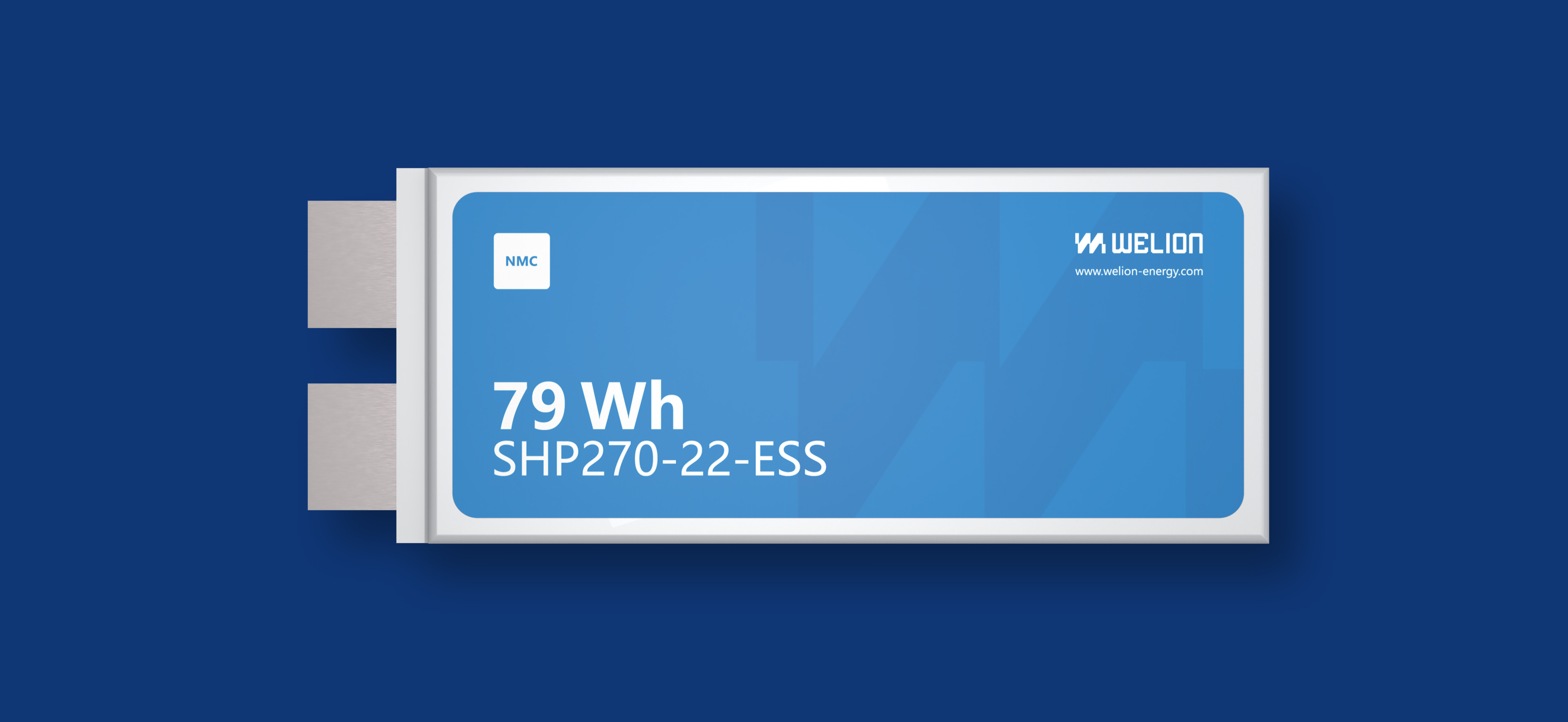

Strategic WELION decision to enter motorcycle and LEV market. Products:

>= 310 Wh/kg

>= 670

Wh/l

16 Ah-89 Ah cells

2025

Introduction of new WELION cell formats for E-Bikes Higher Density materials above 360 Wh/kg SOP Cylindrical cells (4695)

2026

Start of 2nd generation technology: WELION Semi-Solid-State Battery Ultra-fast charging for high energy density cells 2C-10C

2027

Next step in energy density

2028

Start of 3rd Generation: Fully solid-state WELION battery Next step in energy density